For electric motor products, bearing system problems have always been a hot topic. More often than not, motor manufacturers, in particular, will simply attribute bearing system failures to bearing quality problems. Some motors have their bearings replaced frequently, but the problem is never solved, because the fundamental problem is not necessarily the bearing itself, but the shaft current causing trouble.

From the analysis of the mechanism of current formation, the main shaft voltage and the closed loop are necessary conditions for the formation of shaft current. In previous tweets, we systematically analyzed the reasons for the formation of shaft voltage. This article focuses on the impact of shaft current on motor performance.

Before talking about the problem, let's talk about the magnetization of the shaft. I once experienced a faulty motor. When I dismantled the motor, I found that the shaft of the motor showed obvious magnetism and had an obvious adsorption effect on the screwdriver used for disassembly. Shaft voltage is the voltage induced on the shaft due to the asymmetry of the motor's magnetic field, magnetization of the shaft, electrostatic charging, etc. Shaft voltage occurs during the operation of the motor, including the voltage at both ends of the shaft , locally on the shaft, and between the shaft and ground.

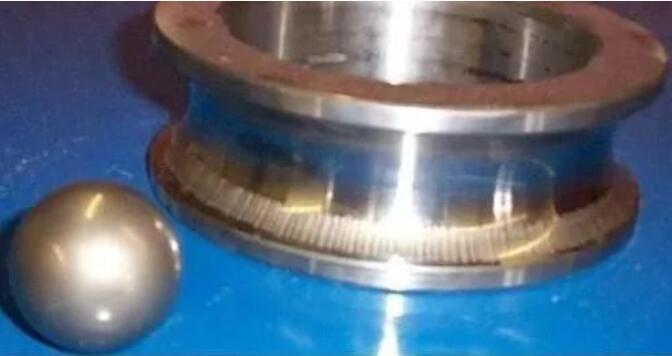

The direct attack target of shaft voltage is the bearing system. When the shaft voltage reaches a certain value, the lubricating oil film (fat film) in the bearing will be broken down, thus forming a closed loop, which generates shaft current. Low voltage and high current are one of the characteristics of shaft current, because the effect of shaft current will cause heating problems, causing the bearing lubricating oil (or grease) to degrade and fail due to excessive temperature. The bearing will be in an intermittent dry friction state, causing the bearing to It may burn itself and cause sintering adhesion between the bearing and the shaft.

Shaft current is an accelerating process of electrical corrosion of bearings. The symptoms are not very obvious at first, and then it will transition to noise. Finally, damage to the bearing operation-related parts will cause the bearing to fall apart and burn out. This process is closely related to the operation of the motor. Depending on the characteristics and severity of the shaft current, some may last longer, while others may only last a few hours.

From a theoretical analysis, most motors have the effect of shaft voltage, but the size is different. The shaft current problem of high-power motors, high-voltage motors and variable frequency motors is more serious, so the design and manufacturing of such motors cannot be the same. Due to the size and power amplification of small motors, necessary shaft current control should be carried out.

We have talked about the causes of shaft current before, such as the asymmetry of the magnetic circuit, capacitive coupling under frequency conversion, electrostatic effect and axial residual magnetism, etc., which will produce shaft voltage. Therefore, it should be carried out from the design, manufacturing and use aspects. Necessary monitoring and protection.

In view of the above analysis, we can draw a conclusion that for motor products, the analysis of bearing system problems should not be limited to mechanical problem analysis. Especially for large motors, generators, etc., electric corrosion analysis of shaft currents should be performed.

Online consultation

If you are interested in our products and want to know more details, please leave a message here and we will reply to you as soon as possible.